Ship Wall

Case Study in progress

Ship Wall was designed to transcend the run-of-the mill wallcovering. In continuity with the home’s nautical theme, we brought a physicality to the wall that, in concept, transports you to other areas of the home.

Involvement

Product Strategy

User Research

Interaction

Visual Design

Prototyping

Location

Coronado, CA

Scope

-Wallcovering

-Illusion

-maintains home concept continuity

Constraints

-Not a functioning seaworthy ship

-Dimensions do not allow for actual ship scale/proportion (stylized design)

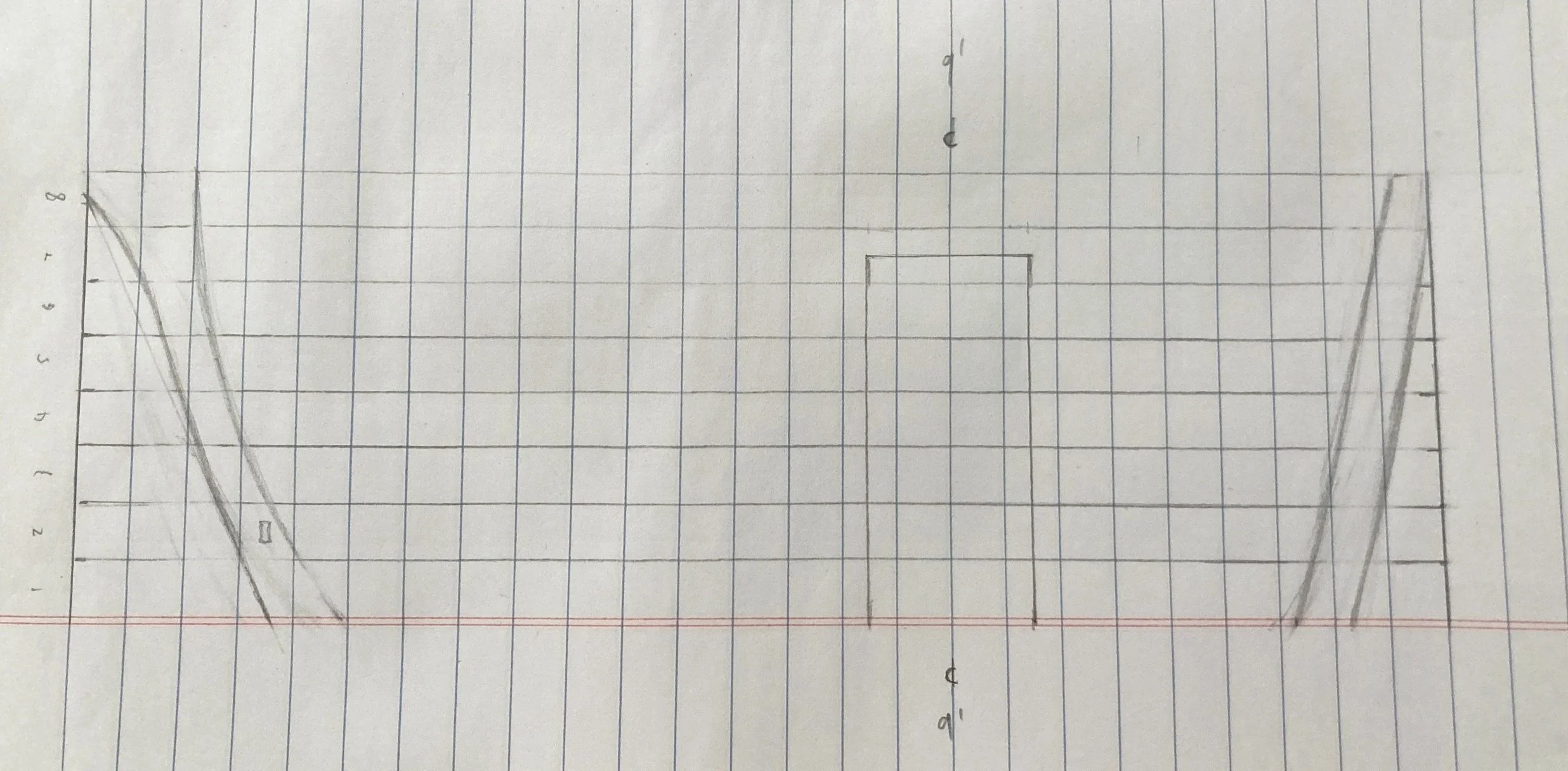

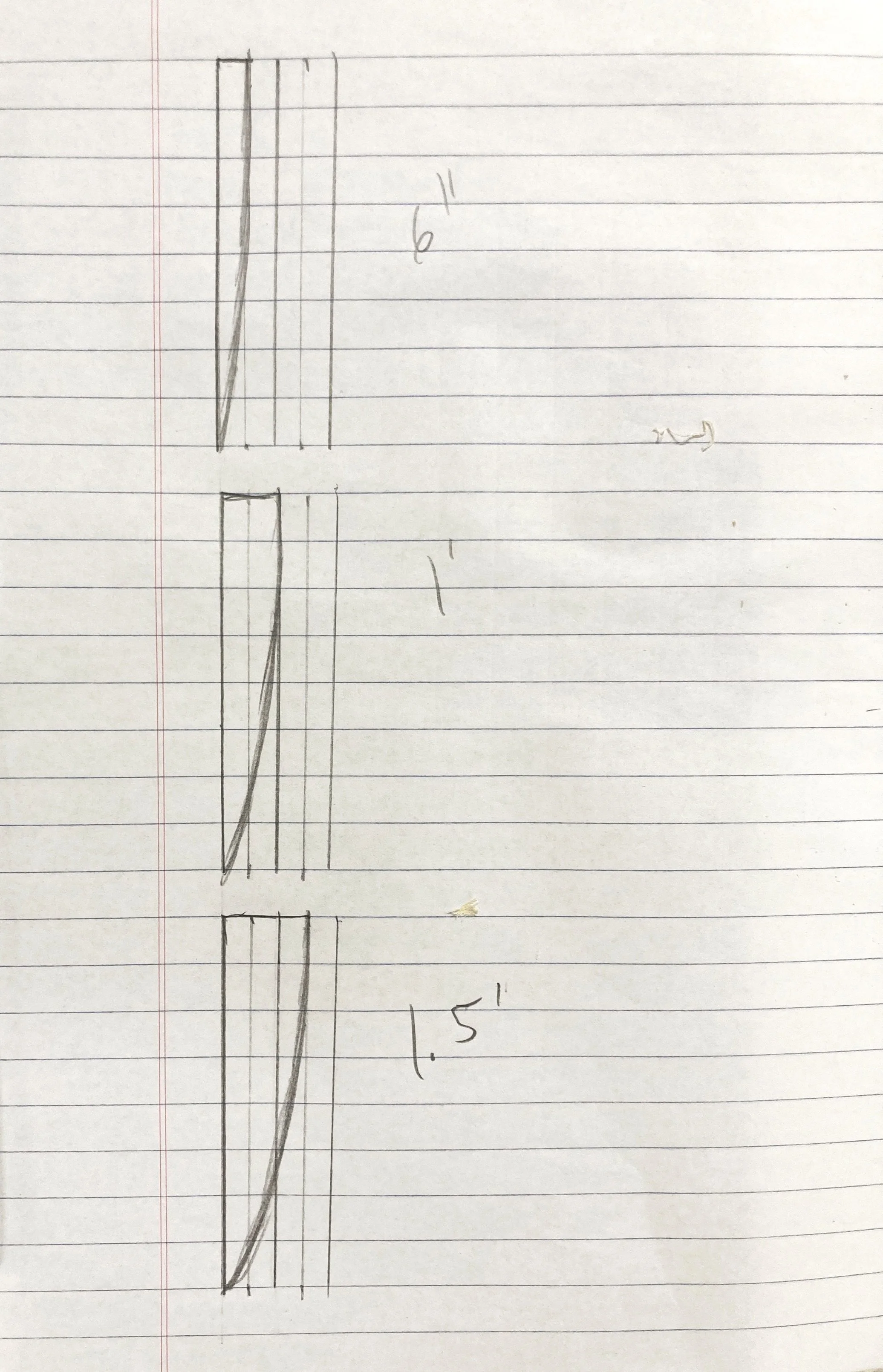

Preliminary sketches (wireframing)

Through preliminary sketching, a build strategy was devised that defined the structural aspects of the ship wall, and provided a starting point for rough framing.

A 1’ x 1’ grid was used to establish contour

Whereas the ship illusion would be optimized using framing members that were a foot and a half in depth when installed, the space was limited by preexisting speakers mounted in the ceiling, less than a foot away. The homeowner decided against relocation of the speakers. Because of this, It was determined that 2x8 framing members would be used, and a 7” depth would be our starting point

Iterations of the layout using the center of the wall as the starting point for the 7” framing members, didn’t produce a reasonable facsimile of a real life ship. Instead, the door leading out to the garage was deemed the optimum starting point based on the contour it would produce.

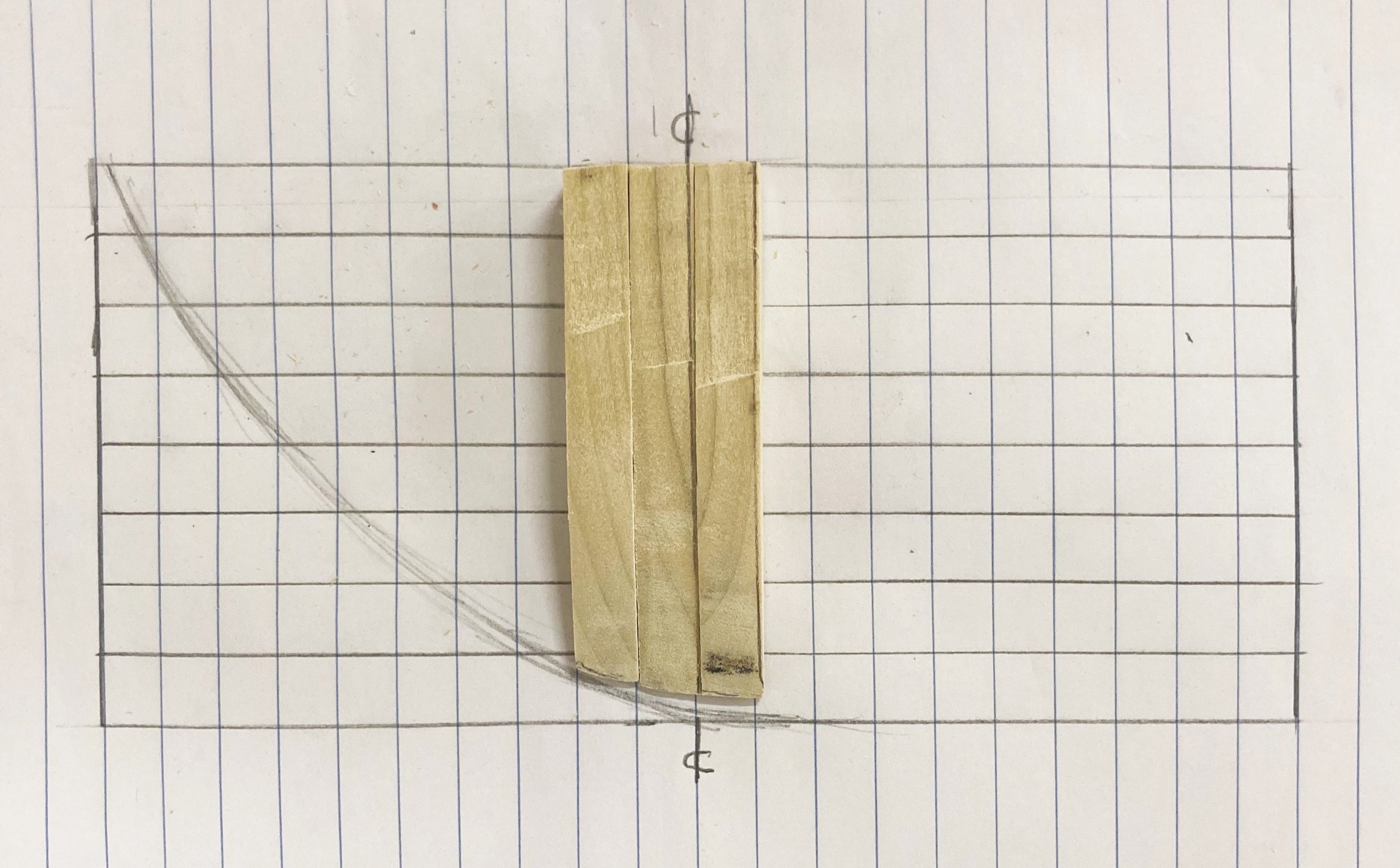

Rough framing (Prototyping)

The ship wall was prototyped during rough framing. To achieve the contour necessary, calculations were made utilizing one vertical framing member “rib” as a template. All other “ribs” were modified based on these calculations.

Skin (Back end development)

The skin of the ship was created using distressed teak plank, and wrapped along the contour of the framing members to create the illusion of a ship coming out of the wall. They were installed with a varying layout pattern, much like flooring, to avoid the viewer fixating on repetitive patterns at the seams where each plank joined the others.

The Bow of the ship (Front end Development)

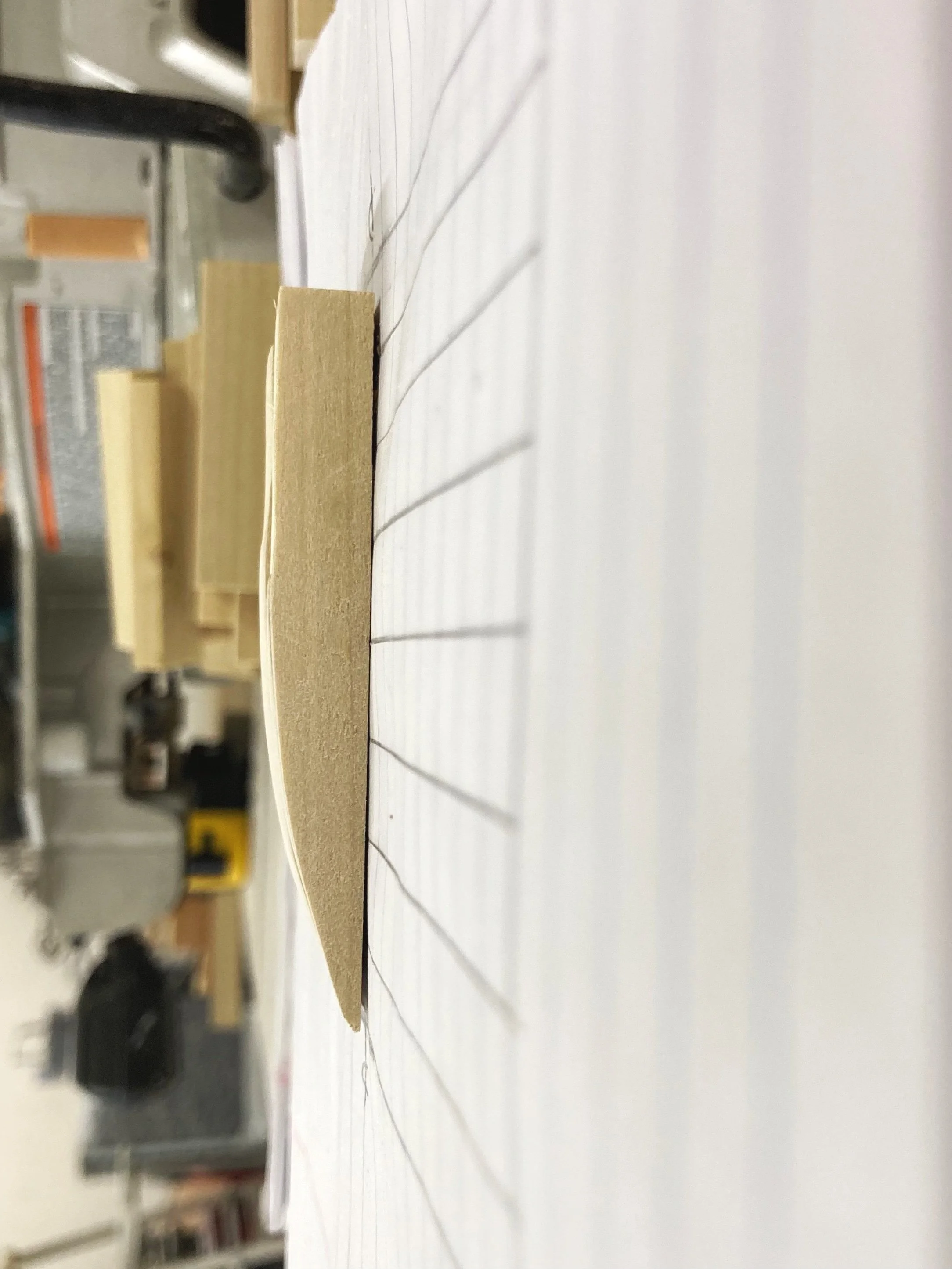

Besides the framing members themselves, another one of the most challenging aspects of the ship wall was the bow (or front) of the ship. Initial sketching provided an indication of contour dimensions in a general sense, but like the “ribs”, prototyping was necessary to ensure that the final product fit snug and suited the intended purpose.

Pieces of plywood were cut and joined together to establish curve.

A final prototype of the bow was made, and dry fit to create a template for the final teak trim piece to be crafted from.

Because of the shape and curve of the bow trim piece, multiple pieces of teak were glued and biscuit joined to be cut into the shape of the trim piece

Finishing touches (UI)

Once the framework was skinned and bow trim was complete, there were a few finishing touches to be added.

A custom teak doorjamb was made, and strips of teak were ripped down to serve as trim surrounding the jamb, covering any gaps between plank and jamb.

Gel stain was applied to the lower third of the hull, and a horizontal bronze painted trim strip

It was the clients wish to have a mermaid figurehead for the ship (space permitting). Because the proportions wouldn’t accommodate for this, we settled upon a custom graphic to be created and applied to the bow area.